In the competitive world of U.S.A. manufacturing, precision, durability, and cost-efficiency are crucial. Brass turned parts have become increasingly popular due to their unique combination of strength, corrosion resistance, and versatility. These parts are essential in a variety of industries, and their demand is on the rise.

This blog highlights how brass turned parts are transforming U.S.A. manufacturing, offering key benefits, and why choosing the right supplier matters.

1. Brass Turned Parts: A Versatile Solution

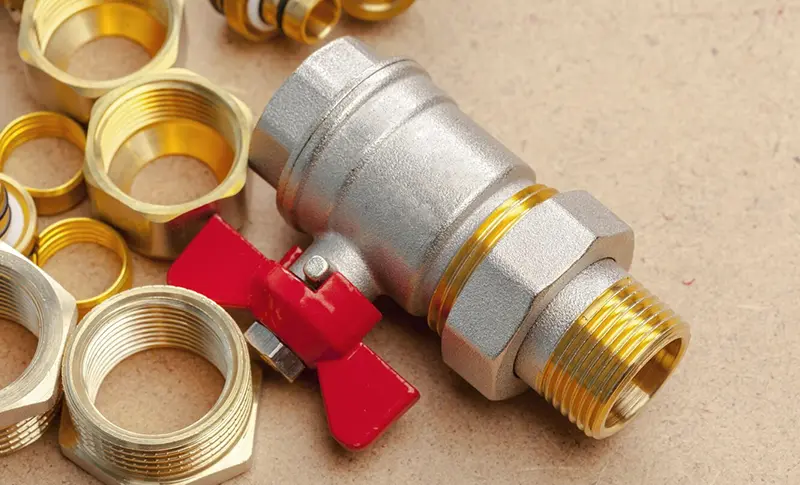

Brass turned parts are made from brass alloys, crafted through a turning process that shapes the material into precise components. These parts are used in countless applications, such as:

Connectors Fittings Fasteners Valves Electrical components

Known for their accuracy, brass turned parts are integral to industries ranging from automotive to electronics.

2. Key Advantages of Brass in U.S.A. Manufacturing

-

Durability and Strength

Brass is an incredibly durable material, perfect for parts that face high wear and tear. It’s commonly used in industries that require robust components, such as automotive, aerospace, and industrial machinery. Brass’s strength ensures long-lasting performance in tough environments. -

Corrosion Resistance

Exposed to moisture or chemicals, many materials degrade quickly, but brass stands strong. Its natural resistance to corrosion makes it an ideal choice for plumbing, HVAC, and marine applications. U.S.A. manufacturers rely on brass to create products that maintain their functionality over time, even under challenging conditions. -

Cost-Effective Performance

Despite its high-performance characteristics, brass is cost-effective compared to materials like copper or stainless steel. U.S.A. manufacturers can leverage brass to maintain product quality without overspending, ensuring both affordability and reliability.

3. Industries Relying on Brass Turned Parts in the U.S.A.

Brass turned parts are in demand across multiple sectors in the U.S.A., driving growth and innovation.

-

Automotive Sector

In the automotive industry, precision and durability are critical. Brass is used for various parts, including fuel fittings, brake systems, and connectors. The material's high resistance to heat and wear ensures that automotive components remain reliable under demanding conditions. -

Aerospace and Aviation

Precision is paramount in aerospace, and brass delivers. From connectors to fasteners, brass parts are used to ensure that every component meets the stringent standards required for safe and reliable operation in aviation and space industries. -

Electrical and Electronics

Electrical components must be both durable and conductive. Brass excels in these areas, providing U.S.A. manufacturers with the reliability they need for high-performance electronics. Whether it's for household products or cutting-edge tech, brass parts keep electrical systems running smoothly.

4. Selecting the Right Supplier of Brass Turned Parts in the U.S.A.

Choosing a supplier for brass turned parts is an important decision that can impact the quality and success of your manufacturing operations. Here are the key factors to consider when selecting a supplier:

-

Precision and Quality Assurance

Ensure the supplier uses advanced machinery and technology to produce brass parts that meet the highest standards. Every part should be manufactured to precise specifications and undergo rigorous quality control processes. -

Customization Capabilities

Brass parts often need to be tailored to specific industry requirements. A supplier that offers flexibility in design, dimensions, and finishes can provide solutions that are perfectly suited to your unique needs. -

On-Time Delivery

In manufacturing, deadlines matter. Choose a supplier with a proven track record of meeting delivery schedules without sacrificing quality. -

Competitive Pricing

While quality should be the top priority, it's also important to keep costs under control. A reliable supplier will offer competitive pricing, helping you manage your budget while receiving high-quality brass turned parts.

5. Anand Brass: A Trusted Supplier for U.S.A. Manufacturers

Anand Brass is a leading supplier of brass turned parts, trusted by manufacturers across the U.S.A. Here’s why:

-

Precision Manufacturing

Anand Brass uses state-of-the-art equipment to create parts with high accuracy and tight tolerances, ensuring a perfect fit every time. -

Customization Options

Whether you need custom sizes, finishes, or material specifications, Anand Brass can provide tailored solutions to meet your exact requirements. -

On-Time Delivery

With a commitment to timely deliveries, Anand Brass helps manufacturers stay on schedule and keep production running smoothly. -

Affordable Solutions

Anand Brass offers high-quality brass parts at competitive prices, making it easy for U.S.A. manufacturers to stay cost-effective while ensuring quality.

#BrassTurnedParts #BrassComponents